ACCS™ Control System

TEC’s Autoclave service expertise is not limited to the actual pressure vessel – it includes a full line of upgrades, including the Autoclave computer controls. The computer controls plays a significant role in how your Autoclave functions, performs and cures your parts both safely and effectively. Please ask about our ACCS™ Autoclave Computer Controls Software.

ACCS™ — Autoclave Computer Control System

TEC’s Autoclave Computer Control System (ACCS™)

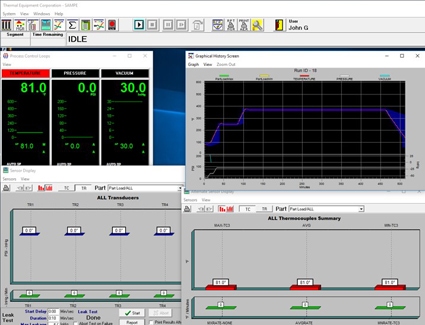

TEC’s ACCS™ software package is designed to control the surroundings that influence the part or parts inside of the Autoclave. The current version of ACCS™ is TEC’s third generation of software for Autoclave control. ACCS™ was designed to run on Windows operating system and works with a basic Intel processor computer. This control system was developed from the experience TEC has gained building Autoclave Systems for over the past 55 years.

TEC’s ACCS™ software is written in house without the use of sub-contractors, in order to provide a high quality engineered control system with the features and functions required by our Customers. This control system is capable of meeting all typical Aerospace specifications. With the purchase of TEC’s ACCS™ software package for your Autoclave system, TEC will provide you with full backup software documentation and disks.

There is no easier way to create and edit cure recipes than with ACCS™ Recipe Manager. Using a logical and intuitive spreadsheet layout, users can quickly view and edit recipe parameters. Extensive error checking helps prevent common mistakes and a Recipe Preview gives a graphical view of the programmed recipe. A built in feature allows the user to manage recipes for several different autoclaves, even when the configurations are different.

Recipe Manager can make following ISO 9000 guidelines much easier as well. Features in ACCS™ and Recipe Manager allow you to store and manage recipes in a central location, a main requirement for revision control.

The ACCS™ will provide you with current state of the art control. TEC’s standard scope of supply with an ACCS™ software package includes current Intel based hardware with a Windows operating system, monitor, color printer, mouse, keyboard and two (2) Ethernet ports. Prior to the shipment, TEC’s ACCS™ software package is preloaded and tested in-house per the customer supplied specification.

A critical feature of TEC’s control architecture is the use of the PLC for ALL safeties and interlocks. This allows the system to remain in a safe and fully controllable condition regardless of the control computer. The PLC logic is also burned into the flash memory of the processor to maintain the logic even during an extended time of having no power and even if the battery fails. An optional HMI Touchscreen is available on all TEC Control system packages.

Touchscreen – HMI

Control System Option – HMI Touchscreen Features

Current technology, and the Thermal Equipment Corporation standard utilize, an Allen Bradley (AB) PLC to duplicate the control functionality and data acquisition of the ACCS™ Computer system. By this approach, you will have extended flexibility as well as increased reliability. One of the features of a new AB PLC is the ability to communicate with the Touch-screen. These components can be modified in the future to accommodate additional functions. The Touch-Screen is available in sizes ranging from 9” up to 15”.

An optional HMI Touchscreen is available on all TEC Control system packages.

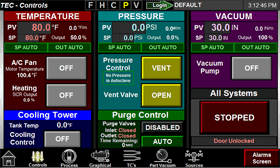

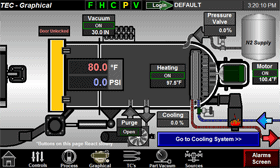

The Touchscreen feature allow you to easily monitor cure runs in real time providing you with ease of access, alarms, status and run time activities. The Touchscreen will include the ability to view all system and part sensor readings. The Touchscreen will provide the following functionality:

- Full control of all Autoclave sub-systems

- Alarm viewing and recording

- Monitor and control of Autoclave Temperature, Pressure and Vacuum providing full back-up control of the Autoclave

- Virtual loop controllers include ramp control feature and manual percentage output control

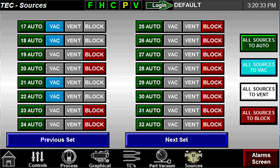

- Manual control of all automated vacuum source lines

- Monitor of ALL part Thermocouples and Transducers. This feature allows the operator to load the Autoclave and verify all of the sensors from the touch-screen

- Backup data acquisition operational anytime Autoclave is in operation

About Thermal Equipment Co.

Over 55 Years of Autoclave Experience

TEC supplies any size aerospace quality Autoclave Systems - everything from a smaller lab-size system, to a 30 foot diameter system. No matter the size, each of our Autoclave systems goes through the same rigorous custom engineering process - resulting in a high-quality Autoclave that is built to your unique specifications.