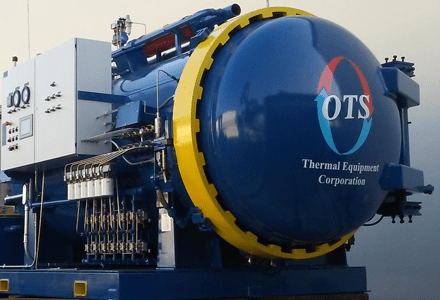

Off-The-Shelf Autoclaves™

Competitively priced and quick delivery Autoclave system ready for installation in three popular sizes. Check out the video below which highlights all the standard features and capabilities of the Off-The-Shelf Autoclave™ product line.

**Pictures of the latest units found below**

Click here for the 4’x8’ Unit

Preproduction model shown. Actual production models may vary.

Key Features

- Skid-Mounted System

- No Pit Required

- 85db Silencer

- Safety Relief Valve

- Standard 165 PSI design, 150 PSI Operating Pressure

- Standard 450 Degrees operating temperature with Electric Heater

- Full Radial Annulus for Proper Airflow and optimum performance

- Maximized Usable Interior Space with up to 2,000 Pound Floor loading

- ACCS, PLC with 9” Color Touchscreen (Computer, Monitor and Printer included)

- Full One (1) Year Warranty

- Two (2) Installation Options

- Quick Delivery Schedule in as little as three (3) weeks

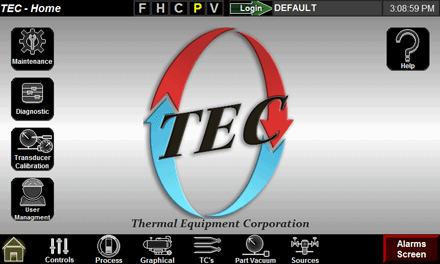

Touch Screen/ACCS™ Features

- Full control of all Autoclave sub-systems

- Alarm viewing and recording

- Monitor and control of Autoclave Temperature, Pressure and Vacuum providing full back up control of the Autoclave

Virtual loop controllers include ramp control feature and manual percentage output control - Automatic and manual control of all vacuum source lines

- Monitor of ALL part Thermocouples and Transducers. This feature allows the operator to load the Autoclave and verify all of the sensors from the touch-screen

- Backup data acquisition operational anytime Autoclave is in operation

- Monitor of system data, i.e., Fan temp, etc.

- Part Sensor Calibration

- Maintenance utilities including motor run times, system configuration, etc.

- Troubleshooting of subsystems including PLC I/O module status and failures as well as PLC rack communication status

Complete Specification Sheets

-

Features/Description

OTS 3′ x 5′

- Interior Dimensions

-

Effective Diameter (excluding floor)

Effective Length

Floor to Ceiling

Ground to Autoclave floor

Max Interior Loading36 inches

60 inches

33 inches

30 inches

200 Pounds

- Exterior Dimensions

-

Overall Width

Overall Length

Overall Height7 feet

12 feet, 6 inches

7 feet

- Temperature

-

Max Temperature

Max Heating Rate

Max Cooling Rate

Temperature Uniformity (Steady state)

Max External Shell Temperature450 °F

10 °F per minute

10 °F per minute

± 10°F

140 °F

- Pressure

-

Max Working Pressure

Vessel Design Pressure

Max Pressurization Rate

Max Depressurization Rate

Pressure Deviation150 PSI

165 PSI

10 PSI per minute

10 PSI per minute

± 1 PSI

- Air Circulation

-

Full Radial Air Annulus

Water-cooled fan motor

Easy to remove motor housing

Protection from overheating fan motorSuperior airflow uniformity during the cure cycle and an increased interior working height of nearly 10% compared to systems without an air annulus

Enclosed housing with stainless steel cooling coil

Optional, priced separately upon request

Equipped with thermocouple sensors

- Heating System

-

Heater Type

SCR Heating Control

Part Temperature T/CElectric

Optional SCR, priced separately upon request

4 Type J

- Cooling System

-

Cooling Coil

Cooling Coil Design

Cooling system304 Stainless Steel

Fan Motor and cooling coil full floating to allow for thermal expansion

Trim cooling for precise control

- Vacuum System

-

Computer Controlled Vacuum Sources

Spare Ports for later use/upgrading

Vacuum Source Size

Vacuum Pass-Throughs

Resin Filters

Independent Monitoring Ports2

Optional, priced separately upon request

1/2 inch NPT

Removable for convenient maintenance

Included (Chilled Water Resin Filters optional)

2

- Controls

-

Primary Controller

Control Software

Main Interface via Touchscreen

PLC Control Hardware

Data Acquisition and Measurement System

Full Data Backup Capability

Safeties and Interlocks control

Power Supply backup

Report Printer

Control PanelAllen Bradley

TEC ACCS

Allen Bradley 9″ PanelView

CompactLogix

Via an Allen Bradley PLC

Via Touchscreen

Reduced Risk Using the PLC – Not the Computer

UPS Included

Color

UL Listed

- Power System

-

Primary power

Control powerNote: Options are available for 240 VAC as well as international voltages including 50 Hz.

480 VAC, 3 phase, 60 Hz.

120 VAC, 24 VDC, self contained

- Delivery Information

-

Size

Weight

Estimated Delivery Time7′ x 7′ x 12′ 6″

7,500 Pounds

3 Weeks to 3 Months

- Installation Options

-

Option #1

Option #2

Full Turn-Key installation is expected to take up to two (2) weeks and includes (1) week for Start-Up, Testing, Tuning and Training. Additional time is available per TEC’s Labor Rate Sheet.

Supervision only includes one TEC Field Technician for one (1) week on site for Start-up, Tuning, Check-out and Training. It is assumed that the system is completely installed prior to TEC’s arrival. Additional time is available per TEC’s Labor Rate Sheet.

Complete Specification Sheets

-

Features/Description

OTS 4′ x 8′

- Interior Dimensions

-

Effective Diameter (excluding floor)

Effective Length

Floor to Ceiling

Ground to Autoclave floor

Max Interior Loading48 inches

96 inches

44 inches

27 inches

500 Pounds

- Exterior Dimensions

-

Overall Width

Overall Length

Overall Height8 feet

16 feet, 7 inches

8 feet, 6 inches

- Temperature

-

Max Temperature

Max Heating Rate

Max Cooling Rate

Temperature Uniformity (Steady state)

Max External Shell Temperature450 °F

10 °F per minute

10 °F per minute

± 10°F

140 °F

- Pressure

-

Max Working Pressure

Vessel Design Pressure

Max Pressurization Rate

Max Depressurization Rate

Pressure Deviation150 PSI

165 PSI

10 PSI per minute

10 PSI per minute

± 1 PSI

- Air Circulation

-

Full Radial Air Annulus

Water-cooled fan motor

Easy to remove motor housing

Protection from overheating fan motorSuperior airflow uniformity during the cure cycle and an increased interior working height of nearly 10% compared to systems without an air annulus

Enclosed housing with stainless steel cooling coil

Optional, priced separately upon request

Equipped with thermocouple sensors

- Heating System

-

Heater Type

SCR Heating Control

Part Temperature T/CElectric

Optional SCR, priced separately upon request

6 Type J

- Cooling System

-

Cooling Coil

Cooling Coil Design

Cooling system304 Stainless Steel

Fan Motor and cooling coil full floating to allow for thermal expansion

Trim cooling for precise control

- Vacuum System

-

Computer Controlled Vacuum Sources

Spare Ports for later use/upgrading

Vacuum Source Size

Vacuum Pass-Throughs

Resin Filters

Independent Monitoring Ports4

Optional, priced separately upon request

1/2 inch NPT

Removable for convenient maintenance

Included (Chilled Water Resin Filters optional)

4

- Controls

-

Primary Controller

Control Software

Main Interface via Touchscreen

PLC Control Hardware

Data Acquisition and Measurement System

Full Data Backup Capability

Safeties and Interlocks control

Power Supply backup

Report Printer

Control PanelAllen Bradley

TEC ACCS

Allen Bradley 9″ PanelView

CompactLogix

Via an Allen Bradley PLC

Via Touchscreen

Reduced Risk Using the PLC – Not the Computer

UPS Included

Color

UL Listed

- Power System

-

Primary power

Control powerNote: Options are available for 240 VAC as well as international voltages including 50 Hz.

480 VAC, 3 phase, 60 Hz.

120 VAC, 24 VDC, self contained

- Delivery Information

-

Size

Weight

Estimated Delivery Time7′ x 7′ x 12′ 6″

7,500 Pounds

3 Weeks to 3 Months

- Installation Options

-

Option #1

Option #2

Full Turn-Key installation is expected to take up to two (2) weeks and includes (1) week for Start-Up, Testing, Tuning and Training. Additional time is available per TEC’s Labor Rate Sheet.

Supervision only includes one TEC Field Technician for one (1) week on site for Start-up, Tuning, Check-out and Training. It is assumed that the system is completely installed prior to TEC’s arrival. Additional time is available per TEC’s Labor Rate Sheet.

Complete Specification Sheets

-

Features/Description

OTS 6′ x 12′

- Interior Dimensions

-

Effective Diameter (excluding floor)

Effective Length

Floor to Ceiling

Ground to Autoclave floor

Max Interior Loading72 inches

144 inches

66 inches

22 inches

2000 Pounds

- Exterior Dimensions

-

Overall Width

Overall Length

Overall Height10 feet

23 feet, 6 inches

10 feet

- Temperature

-

Max Temperature

Max Heating Rate

Max Cooling Rate

Temperature Uniformity (Steady state)

Max External Shell Temperature450 °F

10 °F per minute

10 °F per minute

± 10°F

140 °F

- Pressure

-

Max Working Pressure

Vessel Design Pressure

Max Pressurization Rate

Max Depressurization Rate

Pressure Deviation150 PSI

165 PSI

10 PSI per minute

10 PSI per minute

± 1 PSI

- Air Circulation

-

Full Radial Air Annulus

Water-cooled fan motor

Easy to remove motor housing

Protection from overheating fan motorSuperior airflow uniformity during the cure cycle and an increased interior working height of nearly 10% compared to systems without an air annulus

Enclosed housing with stainless steel cooling coil

Optional, priced separately upon request

Equipped with thermocouple sensors

- Heating System

-

Heater Type

SCR Heating Control

Part Temperature T/CElectric

Optional SCR, priced separately upon request

12 Type J

- Cooling System

-

Cooling Coil

Cooling Coil Design

Cooling system304 Stainless Steel

Fan Motor and cooling coil full floating to allow for thermal expansion

Trim cooling for precise control

- Vacuum System

-

Computer Controlled Vacuum Sources

Spare Ports for later use/upgrading

Vacuum Source Size

Vacuum Pass-Throughs

Resin Filters

Independent Monitoring Ports6

Optional, priced separately upon request

1/2 inch NPT

Removable for convenient maintenance

Included (Chilled Water Resin Filters optional)

6

- Controls

-

Primary Controller

Control Software

Main Interface via Touchscreen

PLC Control Hardware

Data Acquisition and Measurement System

Full Data Backup Capability

Safeties and Interlocks control

Power Supply backup

Report Printer

Control PanelAllen Bradley

TEC ACCS

Allen Bradley 9″ PanelView

CompactLogix

Via an Allen Bradley PLC

Via Touchscreen

Reduced Risk Using the PLC – Not the Computer

UPS Included

Color

UL Listed

- Power System

-

Primary power

Control powerNote: Options are available for 240 VAC as well as international voltages including 50 Hz.

480 VAC, 3 phase, 60 Hz.

120 VAC, 24 VDC, self containedNote: Options are available for 240 VAC as well as international voltages including 50 Hz.

- Delivery Information

-

Size

Weight

Estimated Delivery Time7′ x 7′ x 12′ 6″

7,500 Pounds

3 Weeks to 3 Months

- Installation Options

-

Option #1

Option #2

Full Turn-Key installation is expected to take up to two (2) weeks and includes (1) week for Start-Up, Testing, Tuning and Training. Additional time is available per TEC’s Labor Rate Sheet.

Supervision only includes one TEC Field Technician for one (1) week on site for Start-up, Tuning, Check-out and Training. It is assumed that the system is completely installed prior to TEC’s arrival. Additional time is available per TEC’s Labor Rate Sheet.

About Thermal Equipment Co.

Over 55 Years of Autoclave Experience

TEC supplies any size aerospace quality Autoclave Systems - everything from a smaller lab-size system, to a 30 foot diameter system. No matter the size, each of our Autoclave systems goes through the same rigorous custom engineering process - resulting in a high-quality Autoclave that is built to your unique specifications.